Use Case Overview

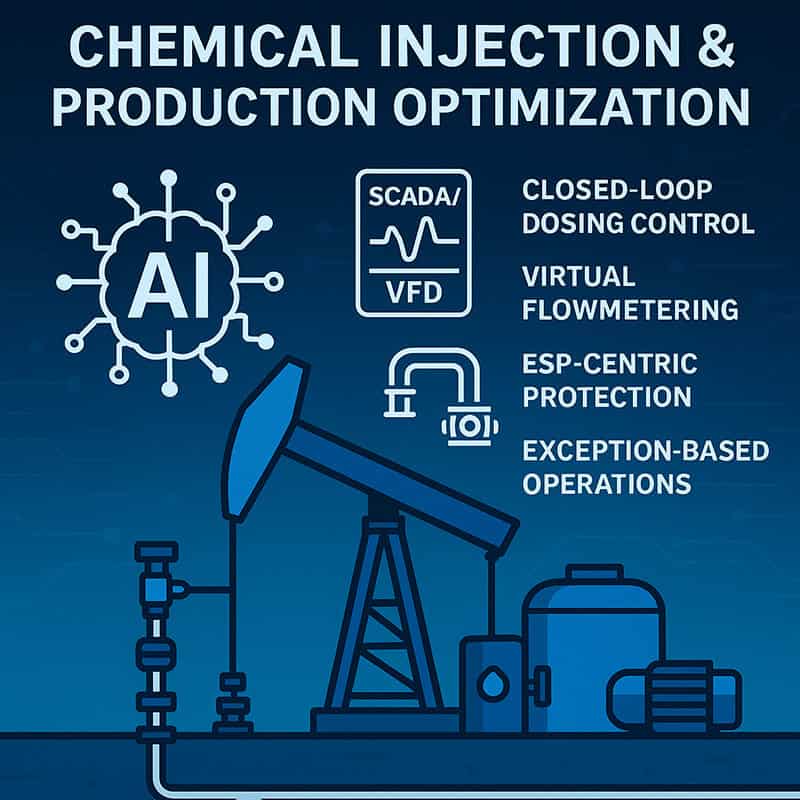

AI-driven chemical optimization enables oilfield operators to balance performance, cost, and reliability across complex production systems.

By combining machine learning, edge analytics, and Microsoft Cloud capabilities, operators can make real-time adjustments that protect assets, improve uptime, and cut chemical spend — all while reducing truck rolls and emissions.

When applied in collaboration with field engineers and production chemists, Smartbridge’s AI-enabled framework has shown strong potential to improve operational efficiency, reduce chemical costs, and extend equipment life.

Strategic Business Goals Supported

Operators realize measurable improvements in production efficiency, safety, and sustainability:

Solution Capabilities

LET’S TALK

Select a time on our calendar & the best Industry & Solutions Expert will meet with you.

There’s more to explore at Smartbridge.com!

Sign up to be notified when we publish articles, news, videos and more!

Other ways to

follow us: