Oracle JD Edwards Warehouse Management System, Explained

Warehouse Management System (WMS) is one of the Oracle JD Edwards EnterpriseOne (JDE E1) key application modules that can significantly improve your operations and supply chain. Unfortunately, many JDE customers remain unaware of its capabilities and benefits. In this blog post, I’ll describe some of the key features and capabilities of this lesser known module.

Article originally published August 2017

The JD Edwards EnterpriseOne Warehouse module is designed to make your warehouse operations more efficient, improve visibility and tracking of inventory, and optimize warehouse space usage. It is an integral part of the Manufacturing and Distribution processes and works in conjunction with many of the JDE E1 product families – including Inventory and Shop Floor Management – to manage inventory and company products.

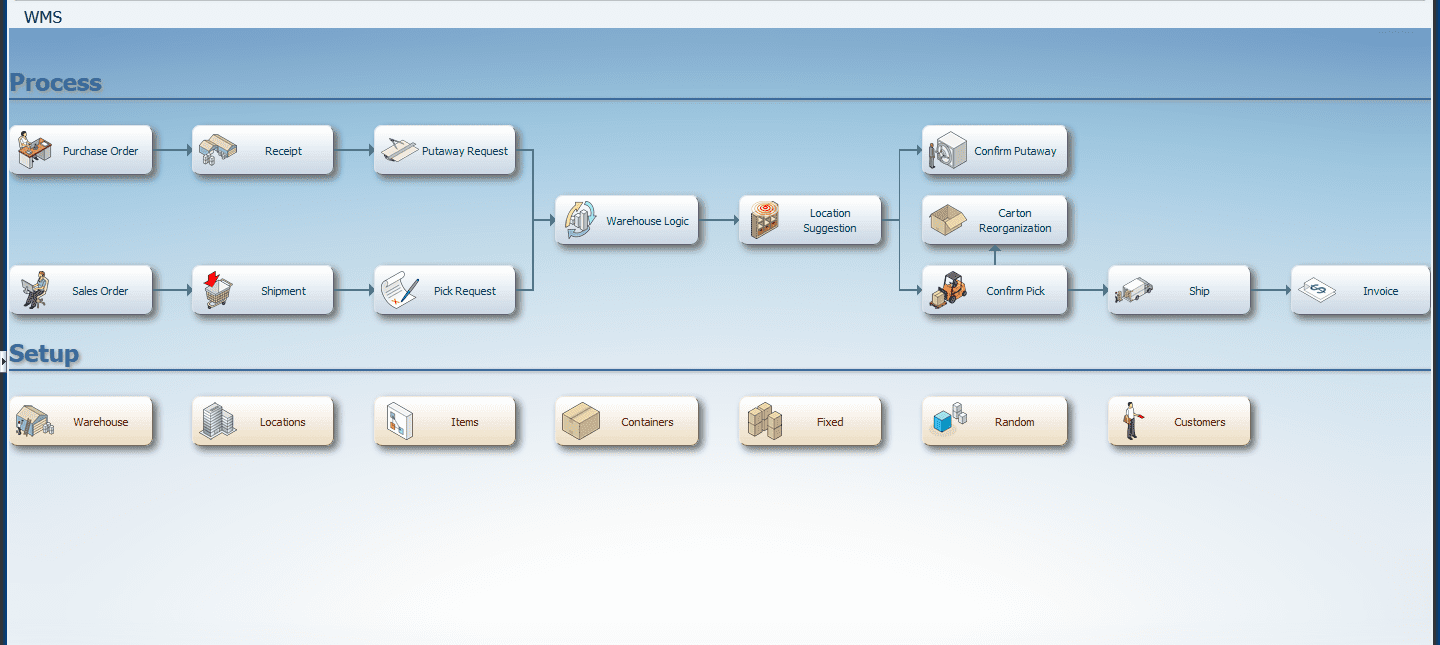

In this example, an E1 page demonstrates the process flow of supporting a Procure to Pay and an Order to Cash solution integrated with WMS capabilities:

Courtesy of Oracle

The Warehouse Management System Process

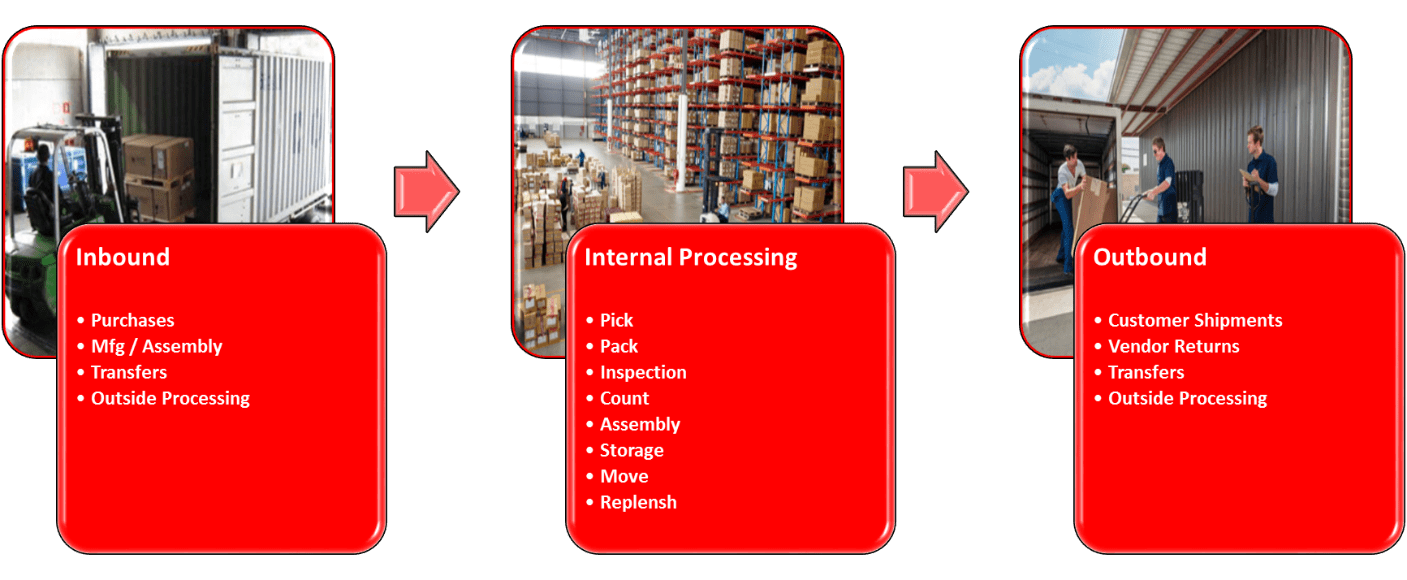

A warehouse management system generally is broken down in the following processes:

The general flow process could be shown as follows:

It is clear from this overview that any Warehousing System needs to support a wide variety of processes coming from a similarly wide variety of transaction sources.

Benefits of a Warehouse Management System

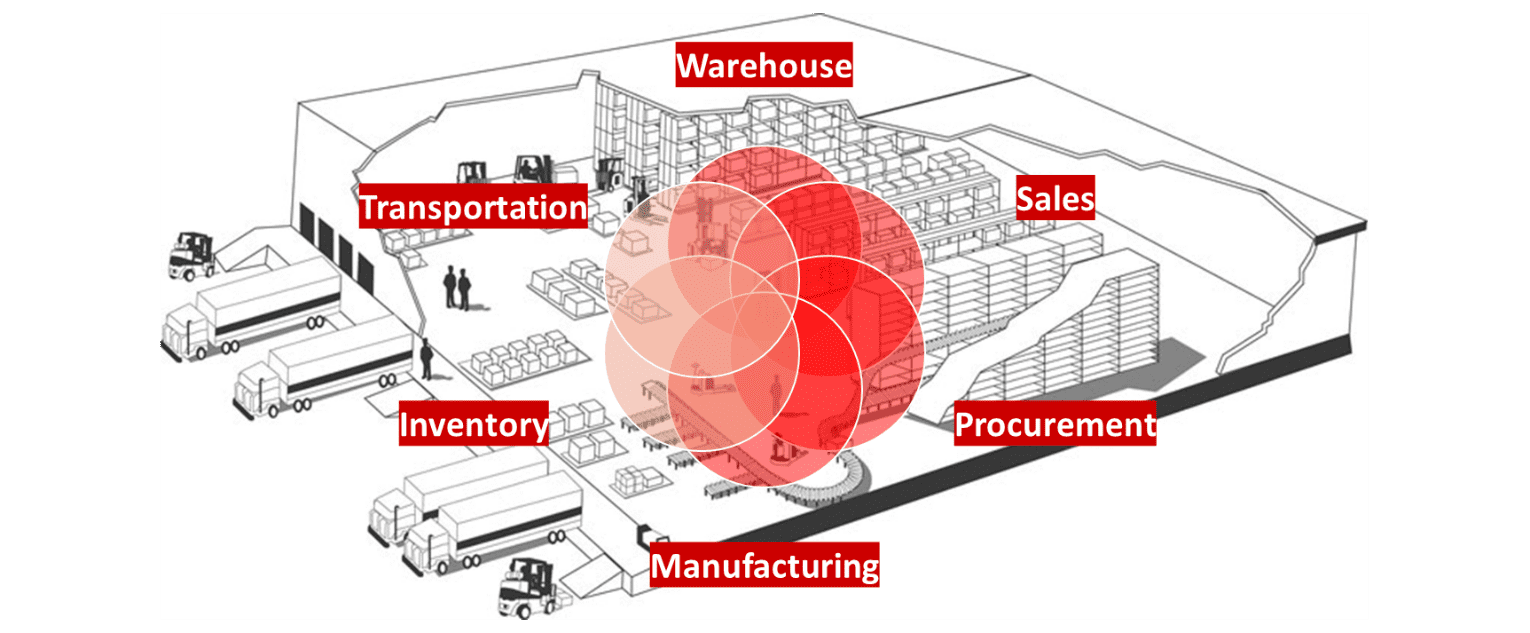

The JDE E1 WMS provides flexible, automated support for better customer service and lower operating costs. Advanced, rules-based stock location and directed movement logic help dramatically improve both the warehouse labor efficiency and space usage. Full integration with sales, purchasing, manufacturing and transportation enables you to meet your customers’ preferences for how they want their orders sourced, made, packaged and shipped.

Some of the benefits that can be identified when WMS is implemented are:

Courtesy of Oracle

Warehouse Management System Features

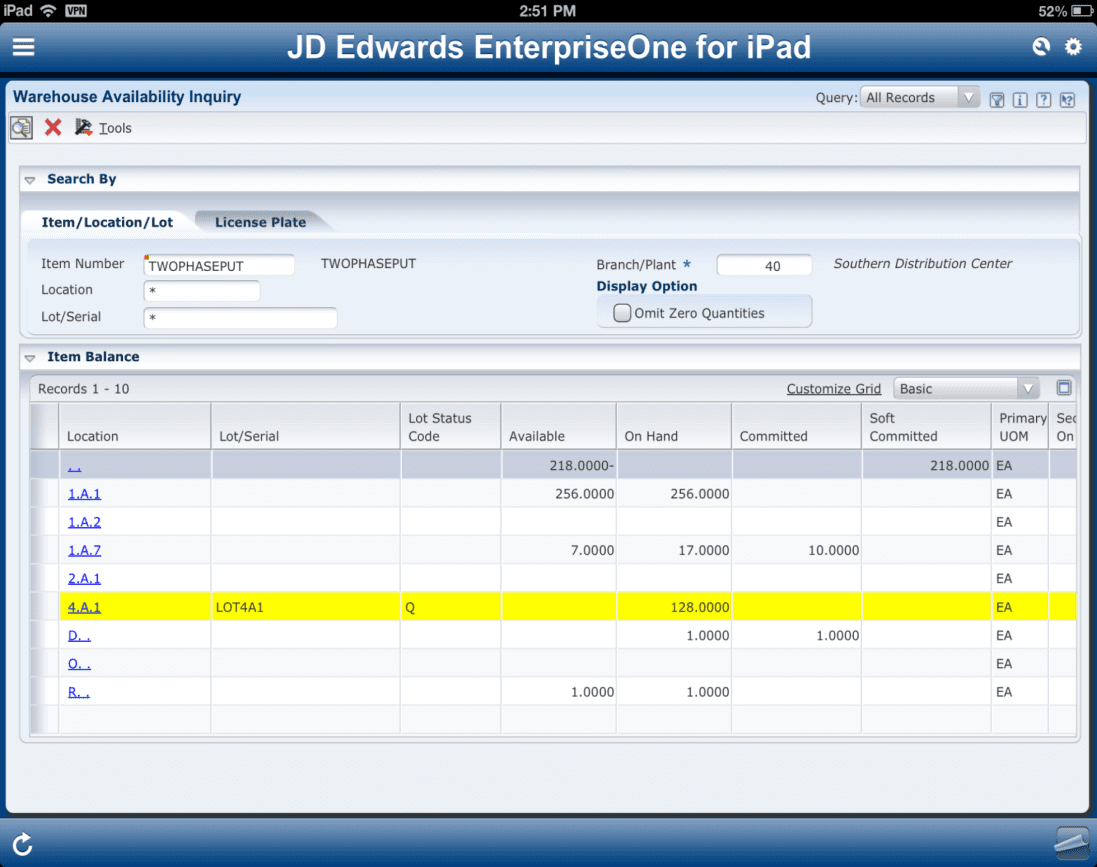

The JDE E1 WMS has many features that address specific warehouse issues. These features are still under development, but Oracle is committed to improving the functionality.

Some of the WMS most important features include:

Courtesy of Oracle

As you can see, WMS is a totally integrated and powerful solution. A WMS implementation can cover a large range of data and setup, so the success of the implementation is based on a deep analysis and detailed definition of the locations, item profiles and program setup. Smartbridge has deep expertise and experience implementing WMS for variety of companies, we recommend staring with a demo, and proof of concept to verify the solution work for your companies’ specific needs. Contact us today for a free demo and discovery workshop.

There’s more to explore at Smartbridge.com!

Sign up to be notified when we publish articles, news, videos and more!

Other ways to

follow us: