Restaurant Group Uses RPA

for Inventory Auditing and Sales Discounts

for Inventory Auditing and Sales Discounts

The Client

Our client is a company that owns, operates, and franchises two well-known restaurant brands. The brands specialize in the operation of fast-casual/quick-service restaurants that offer distinct and unique flavors with broad appeal at a compelling value. The brands specialize in fresh-made cooking, drive-thru service, and catering.

Primary Issues and Objectives

Like many restaurant organizations, our client relied on a physical inventory count method to regularly manage large amounts of stock as well as daily sales discount information for their respective inventory. This resulted in multiple organizational pain points:

The business wanted to reduce the time and manual labor spent on the weekly inventory reconciliation process as well as automate daily sales discounts. They required a solution that would:

Key Challenges

The volume of records and logic behind the inventory metrics needed to classify and filter data presented the biggest challenge to Smartbridge. However, there were various other milestones to overcome in implementing a solution:

Smartbridge Methodology

Smartbridge implemented an agile development approach with short sprints to present POC results in less than 3 days. Support from UiPath was also critical. Regularly reaching out to platform experts enhanced our deliverable skills.

An attended bot was required in the solution implemented. Through the interaction of key users, we input parameters to manipulate the execution according to the metrics needed, as well as cross check the data on each stage of the automation to ensure accuracy. Automatic email notifications ensured communication to each store that needed to recount inventory was done immediately after the validations were completed.

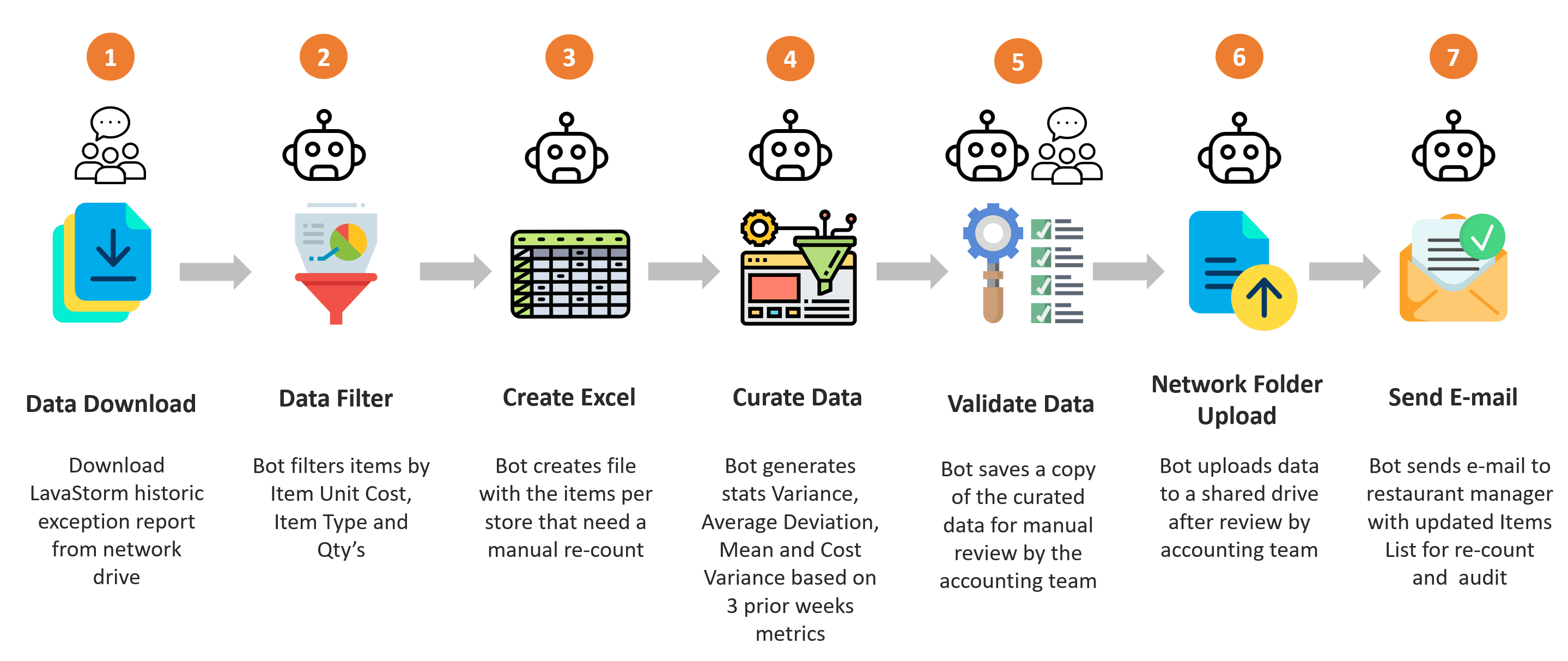

Here’s a look at the steps the bot takes to execute the weekly inventory audit process:

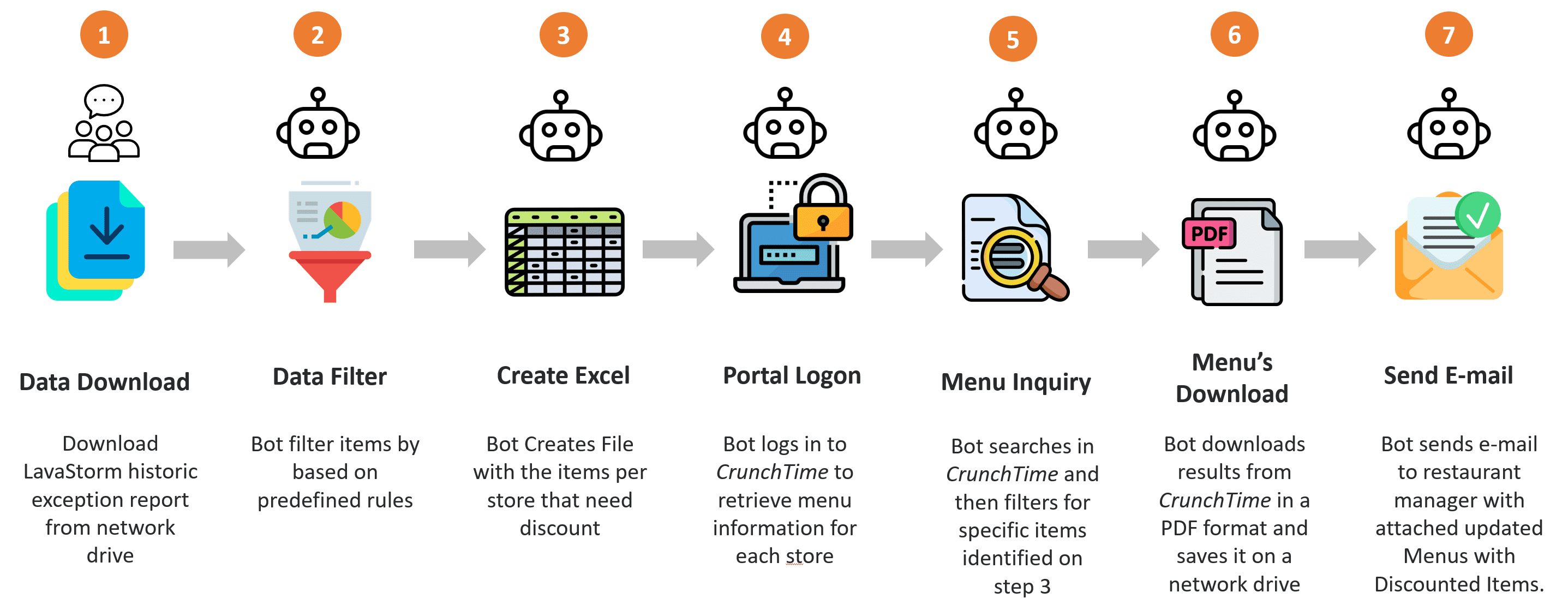

Here’s a look at the steps the bot takes to execute the daily sales discount review process:

The technology stack required to accomplish this project included:

Results

As expected, the POC was a success. The bot was able to read the input data from the inventory audit report and classify the records that needed validation using the metrics defined by the business (weekly cost, deviation of inventory, and standard cost deviation).

The data being filtered was easy to read and properly categorized by item and store. Once the planner completed or adjusted the output report, the bot was able to process that output, and send individual emails to each store detailing items in need or recount. The company received a time savings of 87% per process.

Time saved per process

There’s more to explore at Smartbridge.com!

Sign up to be notified when we publish articles, news, videos and more!

Other ways to

follow us: